Products for Industry

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket) DKG610V

Item Code : 212885

Model : DKG610V

Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket) (DKG610V)

Product Summary

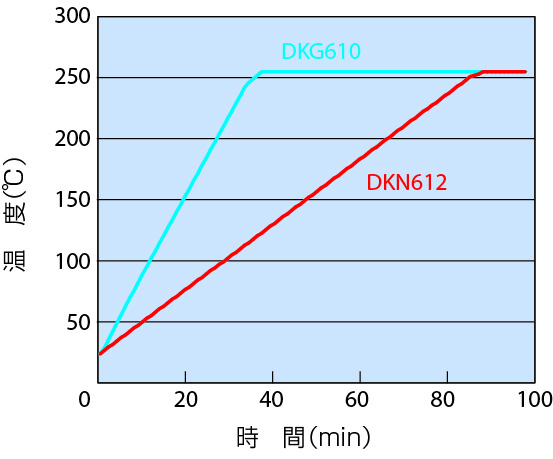

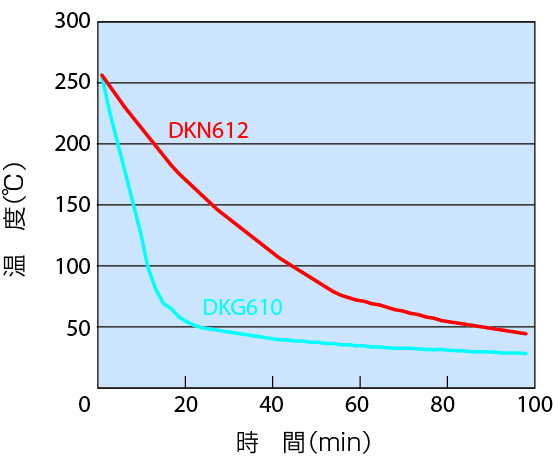

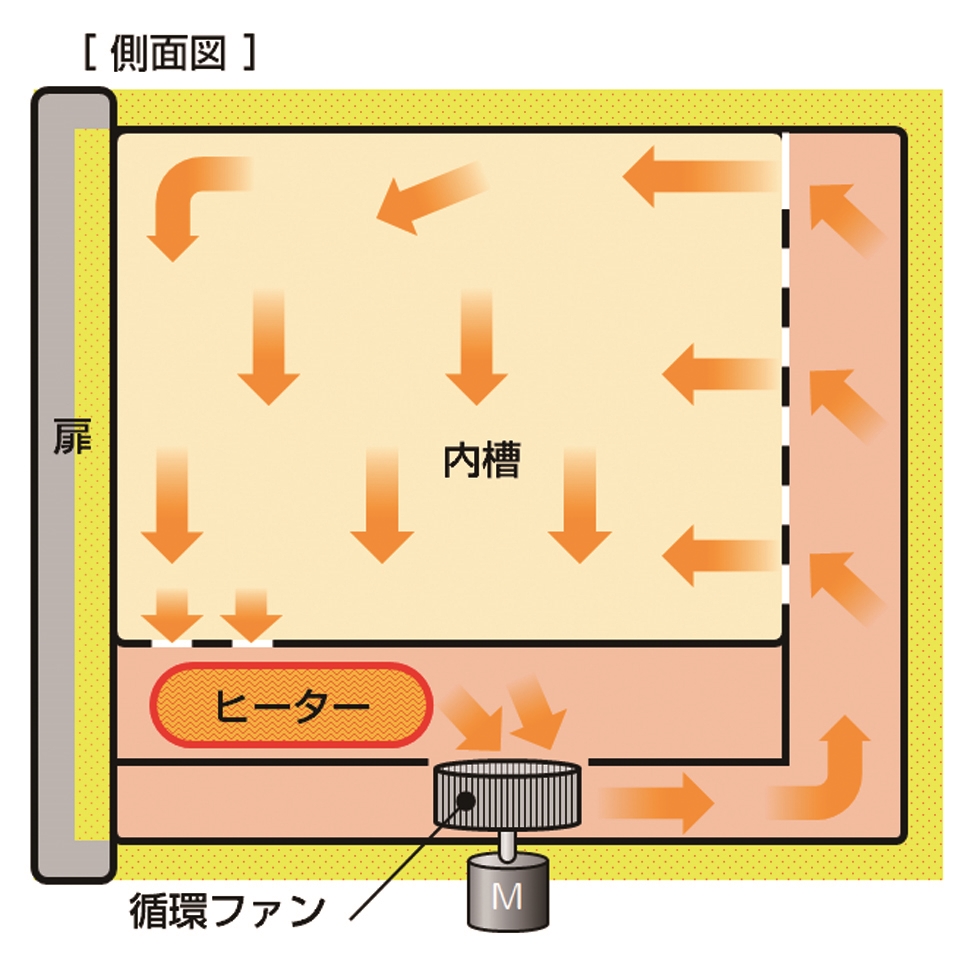

Reduced heating time to 1/2.5, cooling time to 1/4 (compared with conventional company products), horizontal air flow appropriate for loaded operation, the standard oven for production lines supporting multi power supplies. The product lineup includes a silicon free type.

Features of Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket) (DKG610V)

Specifications

Specifications

| Item Code | 212885 |

|---|---|

| Model | DKG610V |

| Method | Forced convection |

| Operating temperature range | Room temp. +30°C to 260°C |

| Temperature adjustment accuracy | ±0.5℃ |

| Temperature distribution accuracy | ±2℃(at 200℃)、±2.5℃(at 260℃) |

| Time to attain max. temp. | Within 45min. from 25°C ->260°C |

| Temp. decrease time | About 30min. from 260°C ->50°C |

| Air supply/exhaust damper | Front operation/manual damper Air supply pipe/exhaust pipe at the rear NSSC180 With exhaust duct |

| Interior/exterior | Stainless steel plate/chrome free electro galvanized steel plate Chemical proof baking finish |

| Heater and heat insulator | SUS pipe heater & glass wool |

| Heater capacity | 200 to 220V 2.6 to 3.15kW |

| Blower fan | Sirocco fan×1 |

| Fan motor | Condenser type motor × 1pc |

| Cable port | I.D.: 30mm One at the right side of the main body |

| Door packing | Fluororubber |

| Air supply port | Bottom of heater room (Open/Close with a manual damper) |

| Damper control | Linked air supply / Exhaust with manual knob on the front of the main body |

| Exhaust port | Upper part of rear of the main body: φ80 (Open / Close with a manual damper) |

| Heater control | SSR control |

| Sensor | K-thermocouple (for temp. adjustment, Indivisual overheating prevesion) |

| Safety unit | Self diagnostic function (Temperature sensor error, Heater disconnection, SSR short-circuit, Automatic overheat prevention function), Key lock, |

| Safety unit | Program lock, Overheat preventive device, Over current electric leakage breaker, Door switch, Temperature fuse, External alarm terminal |

| Internal dimensions(W×D×H mm) | 600×500×500mm |

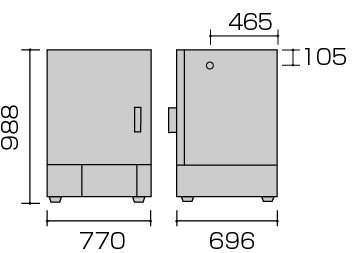

| External dimensions(W×D×H mm) | 770×696×985mm |

| Withstand load of shelf | 15 kg / pc. |

| Shelf support step number | 7 steps |

| Shelf support pitch | 60mm |

| Accessories Shelf | 2 pcs. |

| Accessories Shelf support | 4 pcs. |

| Power Source |

AC200 to 220V

13.5-15A

Single-phase |

| Weight | 110kg |

| Remarks(dimensions) | 150L |

Maintenance and warranty

Conditions: temperature and humidity: 23 deg.C+/-5 deg.C, 65%RH+/-20% (no load)

External dimensions do not include protrusions.