Products for Industry

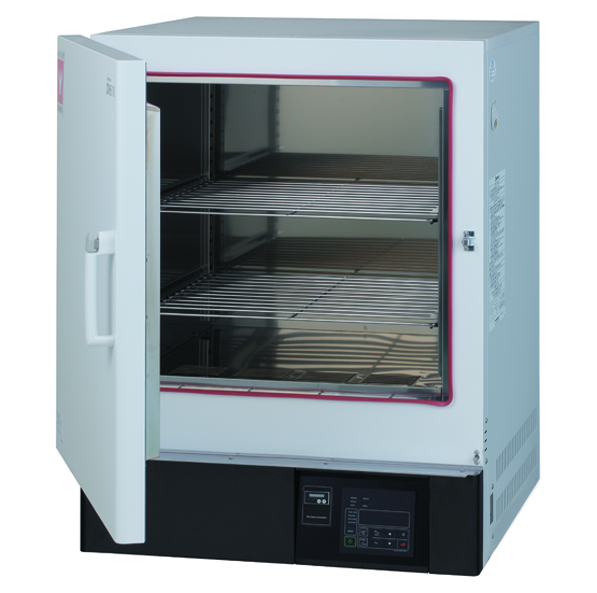

Forced Convection Oven (High Temp.) DN611H

Item Code : 212902

Model : DN611H

Forced Convection Oven (High Temp.) (DN611H)

Product Summary

Industrial & Laboratory Forced Convection

Features of Forced Convection Oven (High Temp.) (DN611H)

- High precision constant oven

- Due to high precision control system, high performance temperature control is realized, and the CO2 discharge, power discharge can be also displayed at the monitor.

- Feature

- Suitable for Heat Insulation Test and Curing Process up to 360deg.C.

- Feature

- Simple Operation by Interactive Key Input.

- Feature

- Calibration offset function, power failure recovery mode , the user configuration information and various function are standard added.

- Feature

- Incorporates with maximum 99 steps, 99 patterns program controller with repeat function.

- Feature

- Loaded with Total Operation Hours Timer.

- Feature

- Data acquisition from internal test device is easy because of cable holes.

Specifications

Specifications

| Item Code | 212902 |

|---|---|

| Model | DN611H |

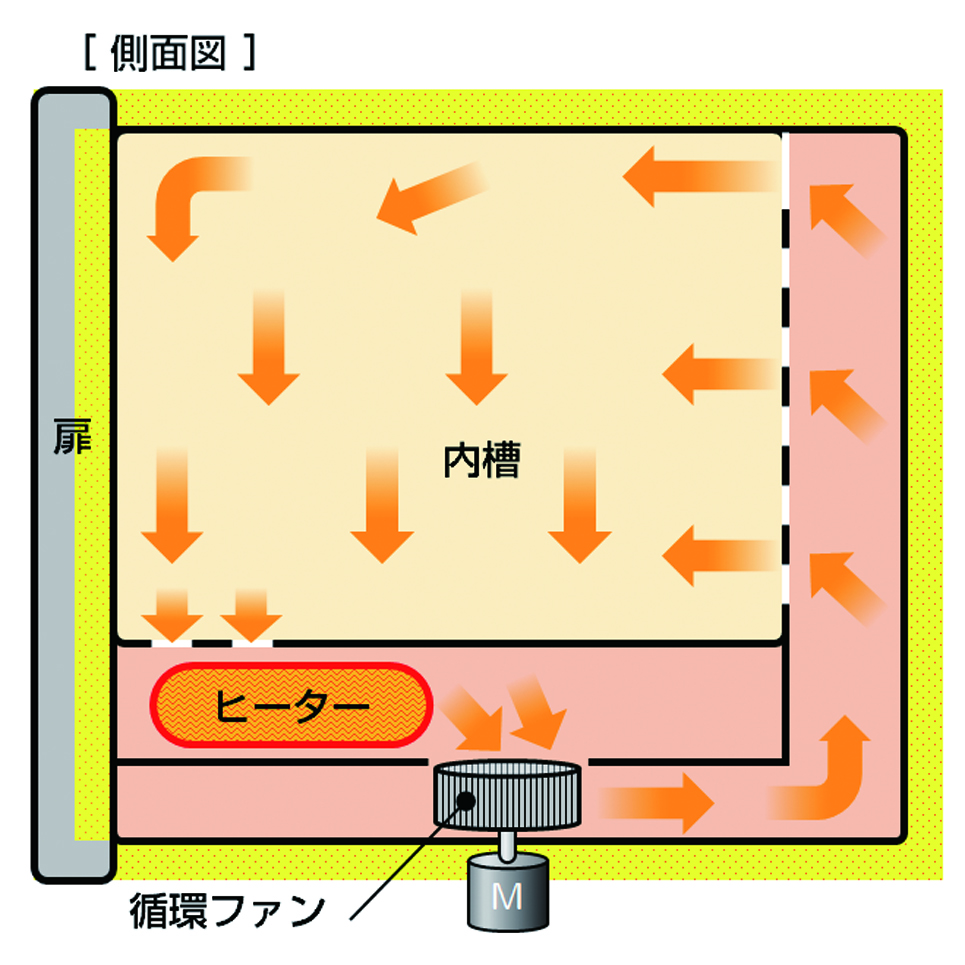

| Convection Type | Forced air circulation |

| Operating Temp. Range | Room Temp.+15~360℃ |

| Temp. Adjustment Accuracy | ±0.2℃(at 360℃) |

| Temp. fluctuation | 1.2℃(at 360℃) |

| Temp. Distribution Accuracy | ±3℃(at 360℃) |

| Temp. Gradient | 20℃(at 360℃) |

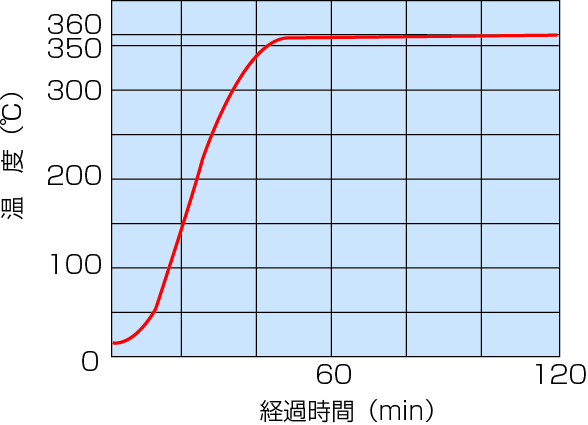

| Time to Reach to Max. Temp. | Approx. 60min. |

| Interior / Heat Insulation Material | Stainless Steel / Glass Wool + Ceramic Fiber |

| Fan | Sirocco Fan, Condenser Type Motor |

| Cable holes | 33mm diameter (right side) |

| Temp. Control Type | PID Control by Micro Computer |

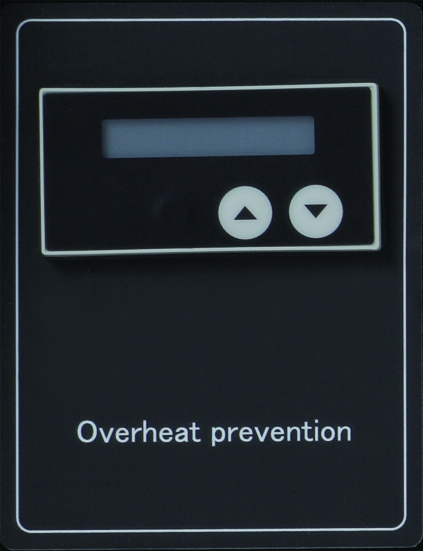

| Temp. Setting Type | Digital Setting by UP/DOWN Key |

| Temp. Display | Digital Indication by Green LED |

| Other Display | Temp. Pattern Display for Operating Display by LED |

| Timer / Timer Resolution | 1min. to 99hrs. 59min. / 1min. |

| Operating Function | Fixed Temp. Operation, Automatic Start, Automatic Stop, Quick automatic stop, Program Operation |

| Additional Function | Calendar time(24 hours), Calibration Off Set Function, electricity consumption, CO2 discharge, Heater output operation display monitor, power failure return mode, user configuration information saving/summoning. |

| Heater Circuit Control / Sensor | Triac Zero-cross Type / K-Thermocouple( for temp. adjustment, individual overheating prevention) |

| Safety Countermeasure | Self Diagnosis Function (Sensor, Heater, Fan, Triac, Main Relay, Automatic Overheat Prevention), Key Lock Function, Independent Overheating Prevention, Door Switch, Electric Leakage Breaker |

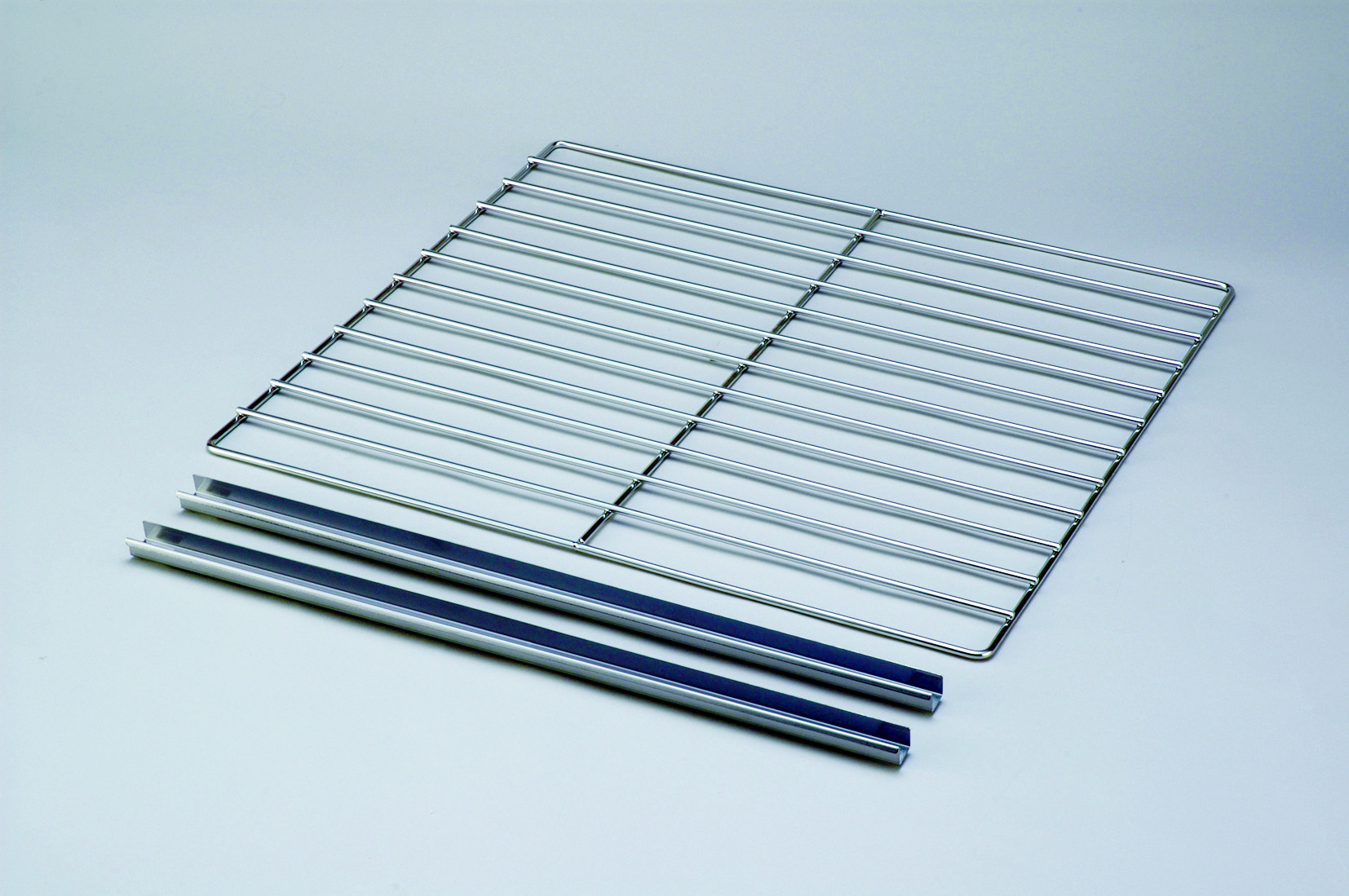

| Shelf Max. Load | Approx. 30kg / shelf |

| Shelf support step number / Pitch | 17pcs. / 30mm |

| Shelf material | Stainless wire |

| Accessories Shelf / Shelf support | 2pcs/ 4pcs |

| Heater | SUS Pipe Heater 4.0kW |

| Exhaust port | 33mm diameter x 2 ( back side) |

| Internal dimensions(W×D×H mm) | 620×600×600mm |

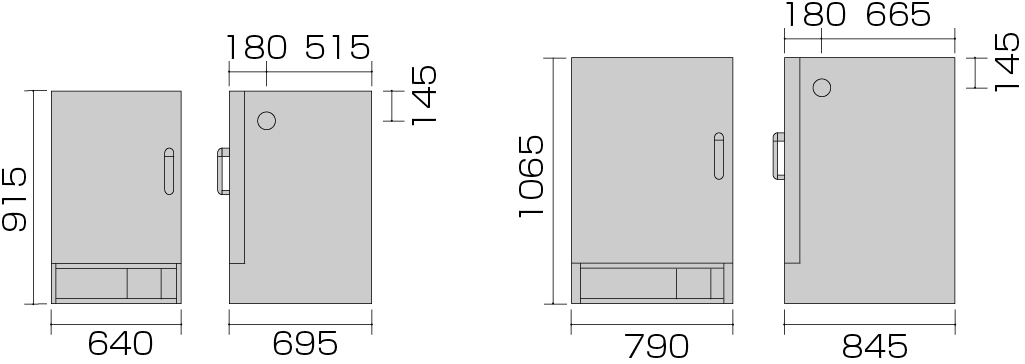

| External dimensions(W×D×H mm) | 790×845×1065mm |

| Remarks(dimensions) | 223L |

| Power Source |

AC220V

20A

Single-phase |

| Weight | 130kg |

Maintenance and warranty

Conditions: temperature and humidity: 23 deg.C+/-5 deg.C, 65%RH+/-20% (no load)

External dimensions do not include protrusions.