Products for Industry

Clean Oven DT411

Item Code : 212612

Model : DT411

Clean Oven (DT411)

Product Summary

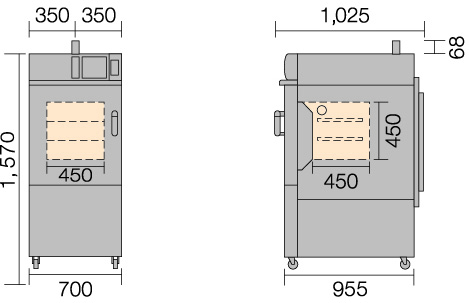

Clean oven suitable for temperature test in dust-free environment.

Features of Clean Oven (DT411)

- Features

- Improvement of visibility of HEPA filter replacement timing by three color indication.

- Features

- Improvement of safety by phase-reversal relay, detecting of incorrect wiring of power supply when installing.

- Features

- Cable diameter changed from 30mm I.D to 33mm I.D when compare withconventional equipments.

- Features

- More options when compare with conventional equipment.

Specifications

Specifications

| Item Code | 212612 |

|---|---|

| Model | DT411 |

| Temp. distribution accuracy | ±4.0°C (at 360°C) JTM K05 |

| Max. temp. reaching time | Approx. 80 min. (at 360°C) |

| Heater | Stainless pipe heater |

| Cable hole | 33mm I.D. ×1 |

| Timer | 1 min. to 99 Hrs. 59 min |

| Operation function | Fixed temp., Auto-start, Auto-stop, Quick auto stop, program (Max.99 steps, 99 patterns, repeat) |

| Circulation method | Forced air circulation |

| Operating temperature range | Room temperature +30~360°C |

| Temp. adjustment accuracy | ±0.3°C (at 360°C) JTM K05 |

| Temp. fluctuation | 1.0°C (at 360°C) JIS |

| Temp. gradient | ±20°C(at 360°C) JIS |

| Clean level | Class 100 (when the temperature is stable) |

| Interior | Stainless steel |

| Exterior material | Cold rolled steel plate with melamine resin baking finish |

| Fan type | Sirocco fan, Condenser type motor |

| Differential pressure meter | Analog type (0~300 Pa) |

| Exhaust port | 61mm O.D.×1 |

| Filter | Heat resistant HEPA filter (dust collect : more than 99.97% at 0.3μm ) |

| Caster | Wheel Dia. 50mm anti-fouling caster |

| Temp. controller | PID control by micro processor |

| Temp. setting method | Digital setting with UP/DOWN key |

| Temp display method | Digital display |

| Other display | Operation monitor (operation condition graphic display by LED patterns) |

| Additional functions | Calendar timer (max. 24 Hrs.), Calibration off-set function, Integration time (max. 65535Hrs.), Display the amount of power consumption/CO2 discharge/Heater operation amount, Power failure recovery mode, User setting information save and recall |

| Heater circuit control | Triac zero-cross control |

| Temp. sensor | K-thermocouple (double sensor) |

| Safety countermeasures | Self diagnosis functions (Sensor, Fan, Heater, Relay, Triac, Automatic overheat prevention), Independent overheat prevention, Key lock function, Electric leakage breaker, Door switch, Reverse phase protection |

| Shelf support step number | 12 steps |

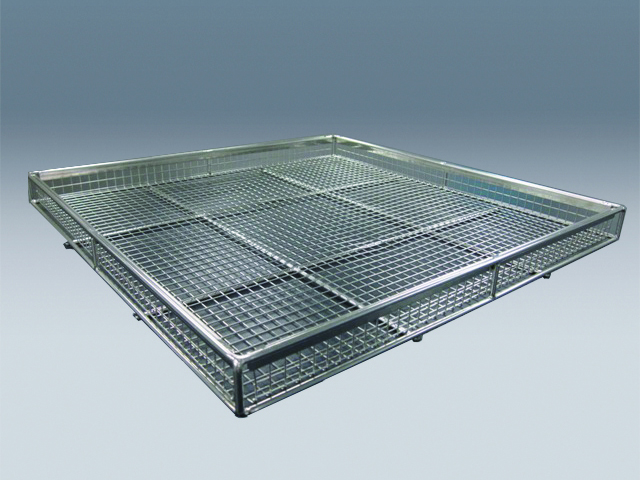

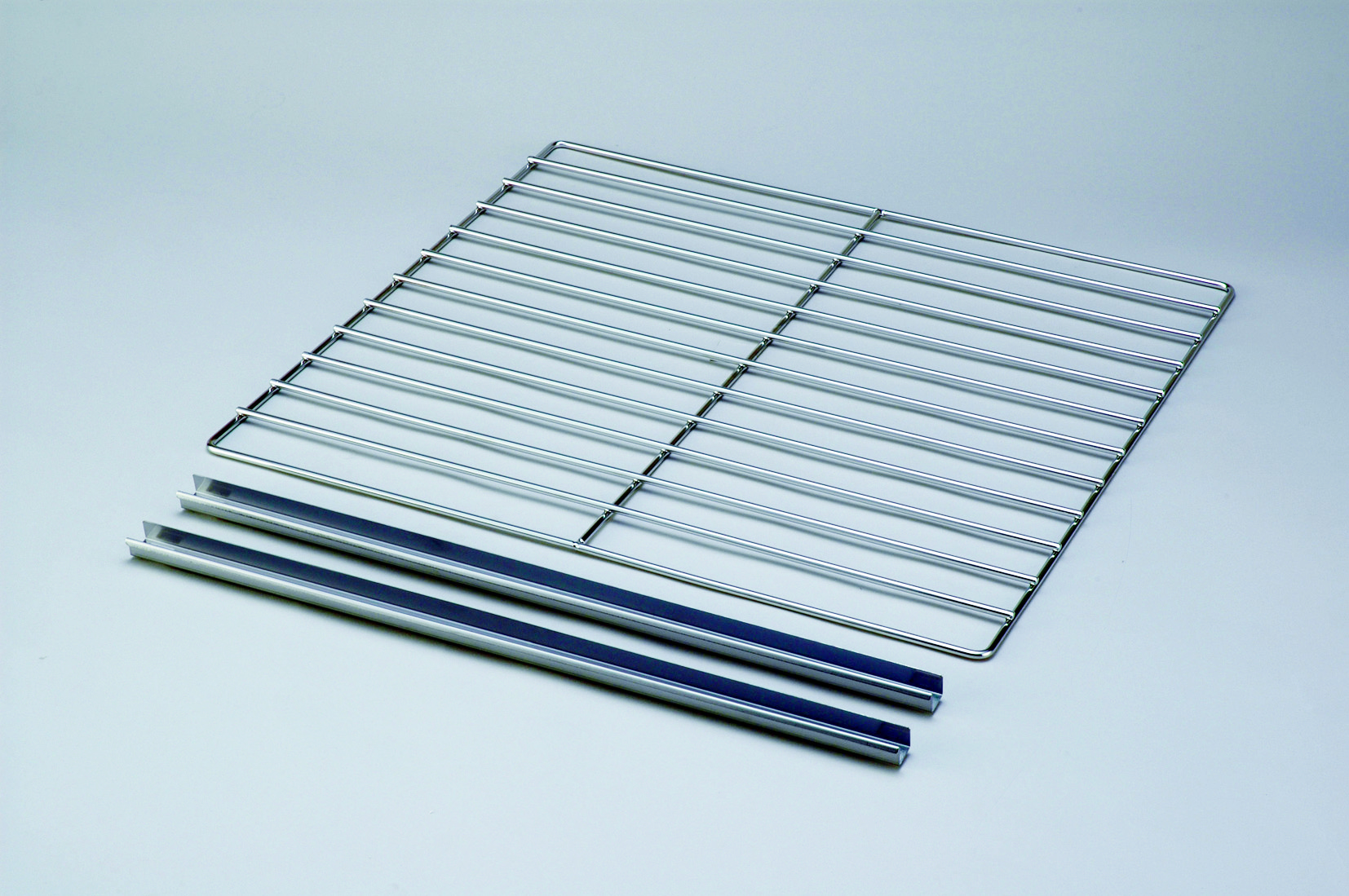

| Accessories Shelf plate | Stainless wire steel, 2 pcs |

| Accessories Shelf support | 4 pcs |

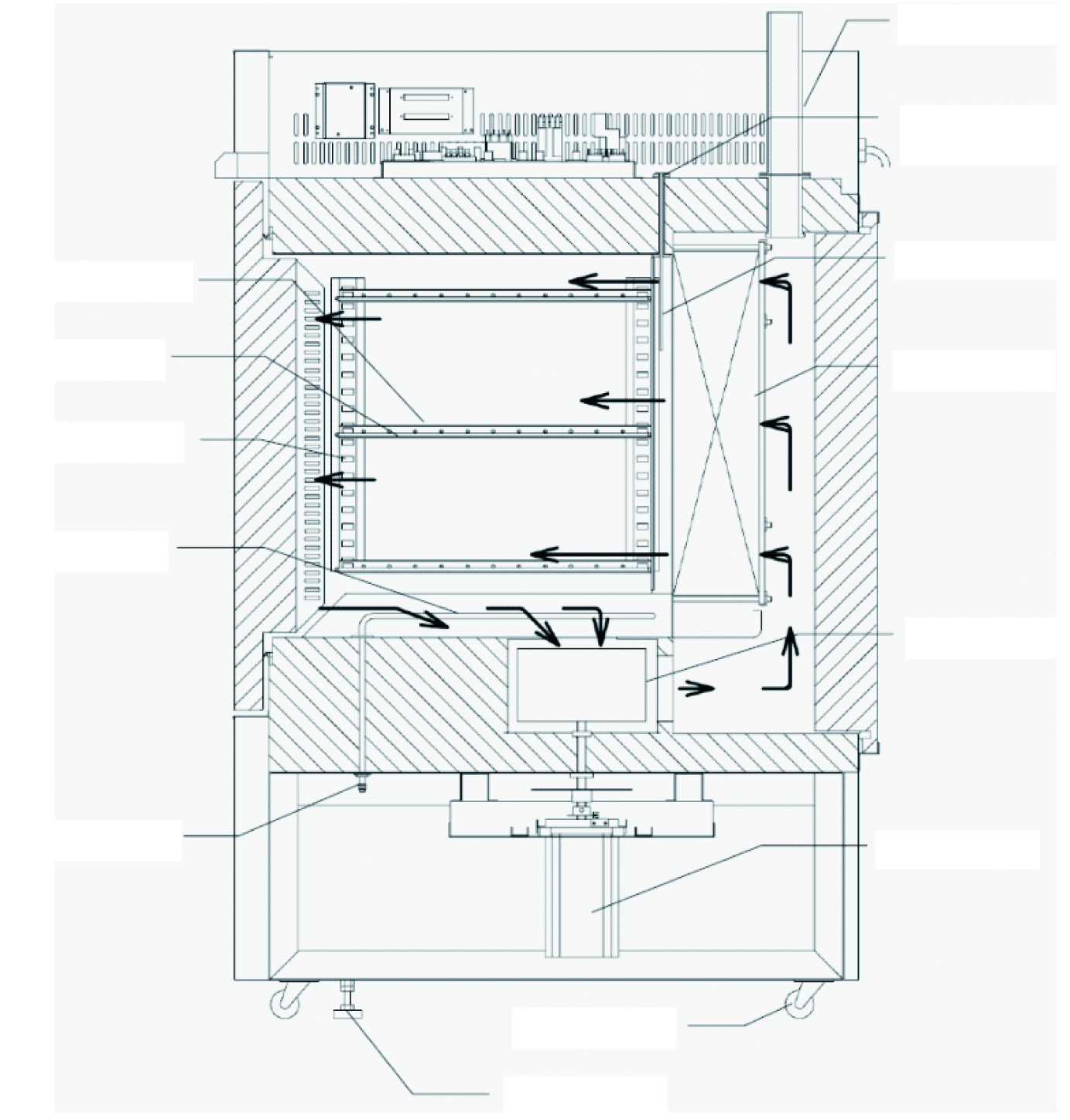

| Internal dimensions(W×D×H mm) | 450×450×450mm |

| External dimensions(W×D×H mm) | 700×1025×1570mm |

| Remarks(dimensions) | 91L |

| Power Source |

AC220/380V

Three phase |

| Weight | 200kg |

Maintenance and warranty

Conditions: temperature and humidity: 23 deg.C+/-5 deg.C, 65%RH+/-20% (no load)

External dimensions do not include protrusions.