Products for Industry

Vacuum Drying Oven (Compact) DP200

Item Code : 212156

Model : DP200

Vacuum Drying Oven (Compact) (DP200)

Product Summary

Wide variation of compact and large scale ovens.

Features of Vacuum Drying Oven (Compact) (DP200)

- Features

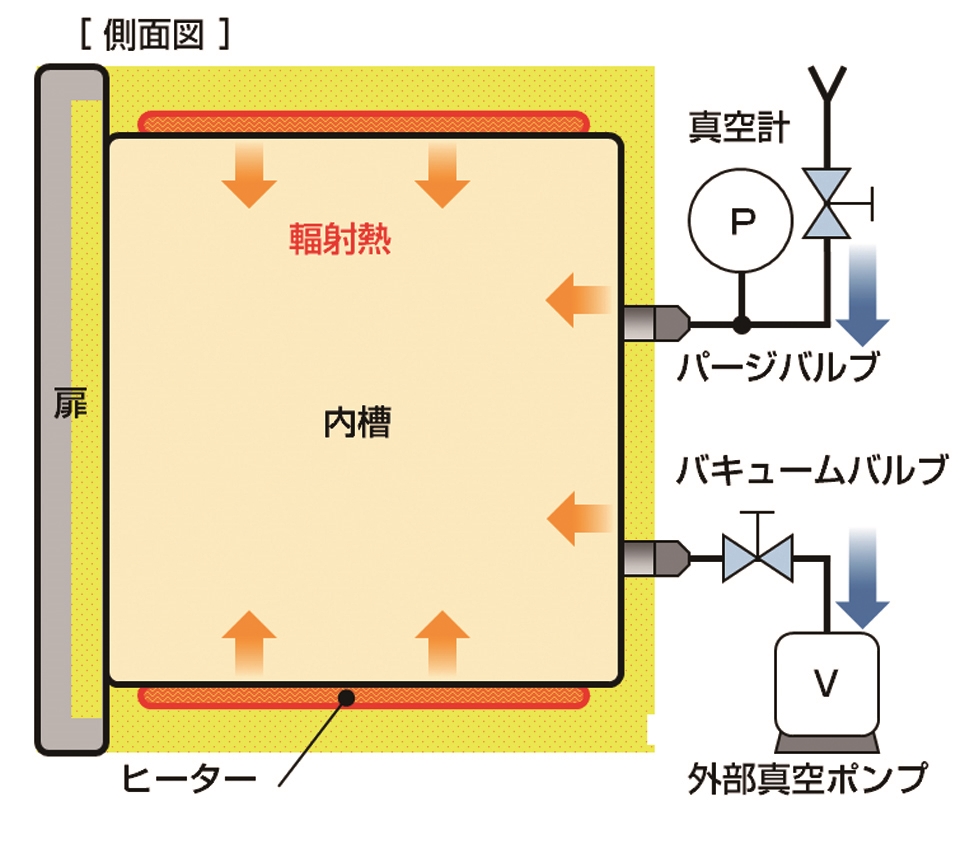

- With a high-accuracy controller system, the DP series is able to attain high tempe-rature with accuracy, also with advanced functionality and safety. The series not only performs curing, annealing, baking, de-foaming, hardening & de-aeration treat-ment, but also has vacuum storage ability and upgraded optional items.

- Shorter drying time & faster heat-up process

- The new Z controller system has been added in the

current PID controller system, which has made the heat-up process faster by 37% (comparing with the previous model) and improved temperature stability when operating in low temperatures. - Easy use & Multi-functional

- User-Friendly control panel and display.

- Easy use & Multi-functional

- Equipped with power consumption / CO2 emission monitor.

- Easy use & Multi-functional

- Various operation mode programmable, auto-start/ auto-stop, timer, calibration offset function, and some more various support functions are equipped as standard.

- Easy use & Multi-functional

- Input/output function (optional) 4-20mA analog output, external communication terminal (RS485), alarm output, operation signal, time-up signal, output port.

- Efficient Safety

- Safety countermeasure

●Self diagnosis functions (temperature sensor abnormal, heater wire broken).

●Independent overheating prevention & electric leakage breaker.

Specifications

Specifications

| Item Code | 212156 |

|---|---|

| Model | DP200 |

| Method | Vacuum drying by decompressed chamber direct heating |

| Max. temp. reaching time | Approx. 60 min. |

| Interior material | Stainless steel |

| Exterior material | Cold rolled steel plate baking coating |

| Door | Single swing door |

| Heat insulating material | Rock wool |

| Heater | Mica heater, 0.68 kW |

| Vacuum gauge | Bourdon tube type, 0 to 0.1 MPa (Gauge pressure) |

| Observation window | Tempered glass and polycarbonate resin plate |

| Temp. control method | PID control by microprocessor |

| Temp. setting method | Digital setting with UP/DOWN key |

| Timer | 0 min. to 99 Hrs. 59 min. |

| Min. division | 1 min. |

| Operation function | Fixed temperature operation, Auto-start operation, Auto-stop operation |

| Additional functions | Calendar timer (max. 24 Hrs.), Integration time (max 65535 Hrs.), Time display |

| Heater circuit control | Triac zero-cross control |

| Temp. sensor | K-thermocouple (Double sensor) |

| Operating temperature range | 40 to 240°C |

| Operatingpressure range | 101 to 0.1 kPa (760~1 Torr) at absolute pressure |

| Temp. Fluctuation | 2.0°C (at 240°C) |

| Pump connection port / Purge port | O.D 18mm / Rc 1/4 |

| Temp display method | Digital display by green LED |

| Safety countermeasures | Self diagnosis functions (Sensor, Heater, Triac, Automatic overheating prevention), Independent overheating prevention, Key lock function, Electric leakage breaker |

| Leakage breaker | 15A |

| Independent cut-out circuit | 0 to 270°C (set temp. range) |

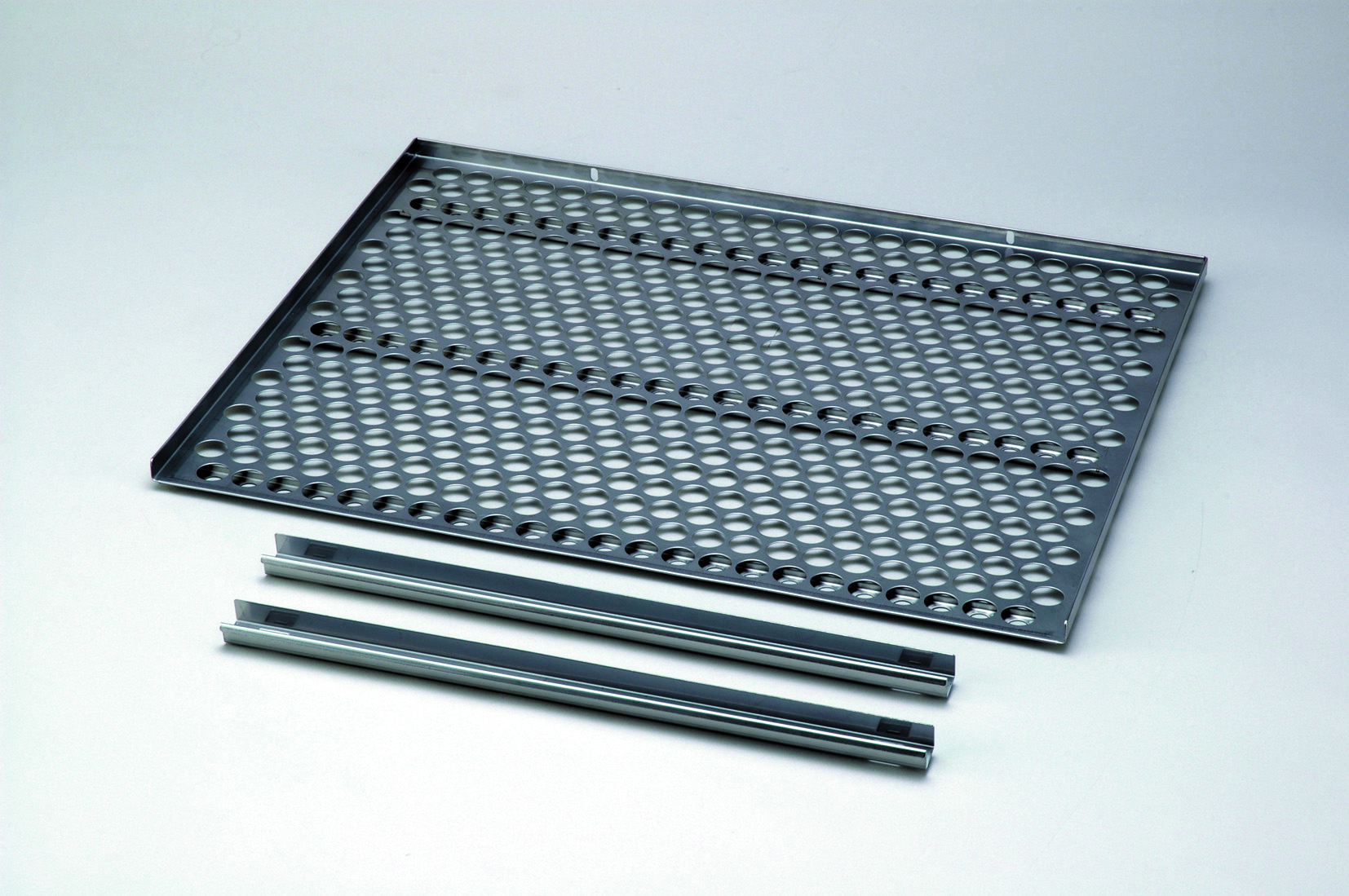

| Shelf support step number | 3 steps |

| Shelf support pitch | 63mm |

| Accessories Shelf plate | Punched stainless steel, 2 pcs |

| Internal dimensions(W×D×H mm) | 200×250×200mm |

| External dimensions(W×D×H mm) | 400×410×682mm |

| Remarks(dimensions) | 10L |

| Power Source |

AC115/220V

Single-phase with step-down transformer |

| Weight | 45kg |

Maintenance and warranty

Conditions: temperature and humidity: 23 deg.C+/-5 deg.C, 65%RH+/-20% (no load)

External dimensions do not include protrusions.