|

Spray Dryer

GA32 |

|

|

A small sized dryer for laboratory use which produces uniformalized fine particles.

The GA32 is a compact spray dryer using a spray dry method which enables simple use for laboratory experiments. It can be used for a wide variety of drying operations, from preliminary examinations for pilot plants to drying operation in general laboratories.

| Water Evaporation |

| Max.1300 ml/h |

| Operating Temperature Range |

| 40deg.C to 200deg.C |

| Liquid Sample Flux |

| up to 28 ml/min. |

| Spray Nozzle |

| for Liquid and Air |

|

|

|

- No danger of damaging foodstuffs, medical products and products that are

sensitive to biochemical-heat.

- No oxidation takes place and the water content of the formed powders is low,

so that there is no contamination.

- Even a solid body of ca.0.5g can be dried.

|

Specifications Specifications |

| |

GB22 (Basic Unit) |

| Structure |

| Heater |

2 kW |

| Aspirator |

Bypass-type blower |

| Sample liquid feed pump |

Quantitative peristaltic pump, flow rate variable up to 28握/min. |

| Stirring system |

Using an induction motor |

| Compressed air blowing system |

Pulse jet system, an electromagnetic valve and electronic timer |

| Temperature control range |

40deg.C to 200deg.C |

| Temperature control accuracy |

±1deg.C |

| Temperature setting and display method |

Digital |

| Dry air flow meter |

Digital display |

| Spray pressure gauge |

Bourdon tube pressure gauge, measuring range : 0 to 0.3MPa (0 to 3kg/cm2) |

| Standard |

| Power source (50/60Hz) |

AC 200/220V, single phase

14A/12.7A |

| External dimensions(W×D×Hmm) |

760×420×1,345 |

| Weight |

Approx. 110kg |

|

|

| |

GF32 (Pulvis Mini Spray Attachment) |

| Structure and Standard |

| Water evaporation rate |

Max. approx. 1,300ml/H |

| Spray nozzle |

Two-liquid nozzle, 1A |

| Drying chamber |

Super-hard glass |

| Cyclone |

Super-hard glass |

| Product vessel |

Super-hard glass |

| Nozzle orifice cleaning |

Pulse jet system (using a compressed air blowing system of Model GB22) |

| Weight |

Approx. 13kg |

|

|

Control

panel Control

panel |

|

Inlet temperature, outlet temperature and drying air volume are displayed digitally. Condition setting dials and stage level control switch are located on the front panel for easy use. Inlet temperature, outlet temperature and drying air volume are displayed digitally. Condition setting dials and stage level control switch are located on the front panel for easy use. |

Obtained powder (example) |

|

In this Spray Dryer, the sample are dried and transformed into a uniform fine powder of amorphous form, so both its solubility and reactivity are extremely high in comparison to crystal. In this Spray Dryer, the sample are dried and transformed into a uniform fine powder of amorphous form, so both its solubility and reactivity are extremely high in comparison to crystal. |

|

Spraying nozzle Spraying nozzle |

Nozzle size (μm)

| Model |

1A |

1 |

2A |

2 |

3 |

| Nozzle No. |

1650 |

2050 |

2050 |

2850 |

2850 |

| (F) |

A |

406 |

508 |

508 |

711 |

711 |

| B |

1270 |

1270 |

1270 |

1270 |

1270 |

| Nozzle No. |

64 |

64 |

70 |

70 |

64 |

| (A) |

C |

1626 |

1626 |

1778 |

1778 |

1626 |

|

|

Model 1A : Standard nozzle

|

Liquid nozzle (F)

|

Air nozzle (A)

|

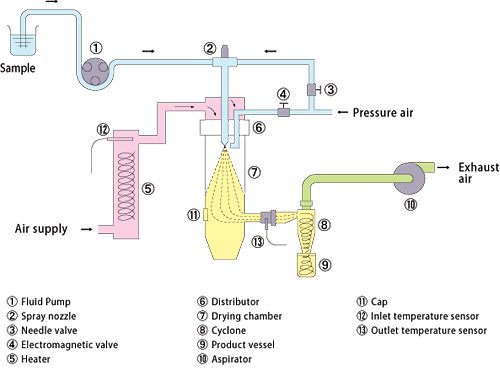

System diagram System diagram |

|

Dimensional drawing (mm) Dimensional drawing (mm) |

|

|