|

Dryer and Granulator, Fluid Bed

GA22 |

|

|

A system to granulate powder of small amount and to dry moist powder.

The GA22 uses a fluid bed and it can be used to granulate powders or to dry moist powders. It is capable of processing samples of between 50g and 300g and well suited for expensive samples and laboratory experiments.

| Processing Capacity |

| 50g to 300g |

| Operating Temperature Range |

| 40deg.C to 200deg.C |

| Liquid Sample Flux |

| up to 28 ml/min.. |

| Spraying Nozzle |

| for Liquid and Air |

|

|

|

- The setting of testing conditions is easily entered from the operation panel.

- The testing mode can be easily observed as the chamber is made of superhard glass.

- Since it is equipped with impellers, consistently good fluid conditions are obtained.

|

Specifications Specifications |

| |

GB22 (Basic Unit) |

| Structure |

| Heater |

2 kW |

| Aspirator |

Bypass-type blower |

| Sample liquid feed pump |

Quantitative peristaltic pump, flow rate variable up to 28握/min. |

| Stirring system |

Using an induction motor |

| Compressed air blowing system |

Pulse jet system, an electromagnetic valve and electronic timer |

| Temperature control range |

40deg.C to 200deg.C |

| Temperature control accuracy |

±1deg.C |

| Temperature setting and display method |

Digital |

| Dry air flow meter |

Digital display |

| Spray pressure gauge |

Bourdon tube pressure gauge, measuring range : 0 to 0.3MPa (0 to 3kg/cm2) |

| Standard |

| Power source (50/60Hz) |

AC 200/230V, single phase

14A/13A |

| External dimensions(W×D×Hmm) |

760×420×1,350 |

| Weight |

Approx. 110kg |

|

|

| |

GF22 (Pulvis Mini Bed Attachment) |

| Structure and Standard |

| Processing capacity |

50 to 300g (batch method) |

| Fluid bed chamber capacity |

3L |

| Spray nozzle |

Two-liquid nozzle used |

| Stirring blade |

Incorporated in the fluid bed chamber (using a stirring system of Model GA22) |

| Filter |

Polyester (carbon fiber mixed PTFE membrane laminate) |

| Filter cleaning |

Pulse jet system (using a compressed air blowing system of Model GB22) |

| Glass parts |

Super-hard glass |

| Weight |

Approx. 13kg |

|

|

Control

panel Control

panel |

Inlet temperature, outlet temperature and drying air volume are displayed digitally. Inlet temperature, outlet temperature and drying air volume are displayed digitally.

Condition setting dials and stage level control switch are located on the front panel for easy use. |

Since a small quantity of samples from 50g to 300g can be treated this device is most appropriate for the treatment of expensive samples and the experiments at the laboratory level. Since a small quantity of samples from 50g to 300g can be treated this device is most appropriate for the treatment of expensive samples and the experiments at the laboratory level. |

|

Spraying nozzle Spraying nozzle |

Nozzle size (μm)

| Model |

1A |

1 |

2A |

2 |

3 |

| Nozzle No. |

1650 |

2050 |

2050 |

2850 |

2850 |

| (F) |

A |

406 |

508 |

508 |

711 |

711 |

| B |

270 |

1270 |

1270 |

1270 |

1270 |

| Nozzle No. |

64 |

64 |

70 |

70 |

64 |

| (A) |

C |

1626 |

1626 |

1778 |

1778 |

1626 |

|

|

Model 1A : Standard nozzle

|

Liquid nozzle (F)

|

Air nozzle (A)

|

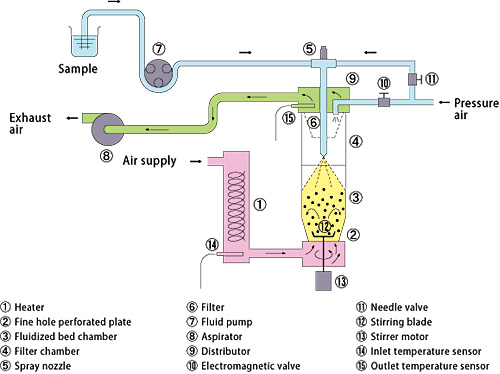

System diagram System diagram |

|

|